Double-sided tapes

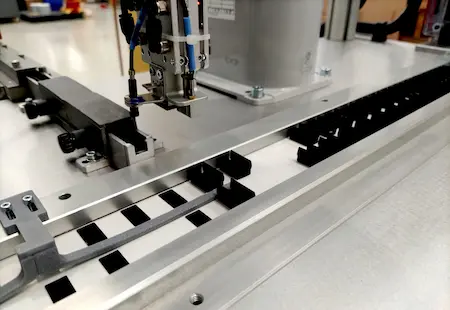

Double-sided adhesive tapes are widely used in all industrial and artisan sectors, for assembly and lamination processes

Double-sided tapes consist of a support coated on both sides with a layer of glue protected by a liner.

An exception is made for transfer tapes which, having no carrier, appear as a simple layer of glue spread on the protective liner. The range of double-sided tapes is very varied and includes specific products for many sectors. This versatility is due to the variety of existing adhesives, supports, and the fact that the coating can be differentiated for the two sides of the tape, generating “asymmetric” products with optimized performance for joining even very different substrates.

Double-sided adhesives always offer new creative opportunities

With double-sided adhesives you can laminate and couple many different materials, modifying their characteristics. Double-sided tapes multiply opportunities and support creativity.

Cleanliness, simplicity and flexibility in assembly operations

Contrary to the use of glues, double-sided adhesives allow clean and immediately movable assemblies, also giving the possibility of creating semi-finished products. Compared to mechanical fixing, they allow tension forces to be distributed across all adhesive surfaces, eliminating weak points. Furthermore, drilling, welding, riveting, etc. operations are avoided. which would “dirty” and make the joints more fragile.

This reduces the impact of manpower, the possibility of error and the number of tools needed, making the work simpler.